Baffle walls play a crucial role in controlling the flow of water within tanks or reservoirs, significantly enhancing the efficiency of wastewater treatment processes. By strategically positioning baffle walls within the system, the turbulent flow is mitigated, allowing for more uniform distribution of wastewater. This controlled flow optimizes the retention time of the water within the reservoir. The increased retention time results in enhanced sedimentation, ultimately leading to better filtration.

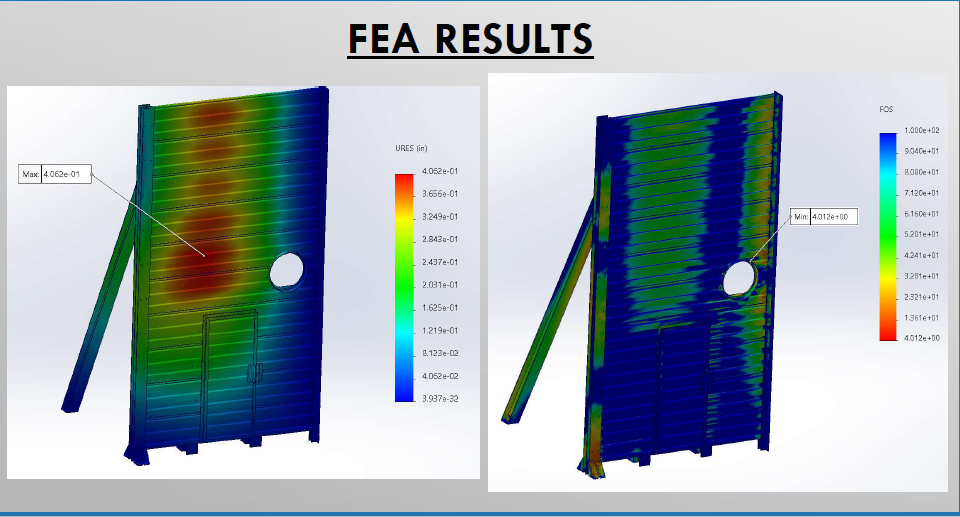

Protectolite’s FRP baffle walls are designed from durable and corrosion-resistant material, offering a long-lasting performance with minimal maintenance requirements. Additionally, their lightweight nature makes them easy to transport and install.

The design flexibility of FRP allows for customization to suit your specific project requirement, ensuring optimal performance and compatibility with various tank configurations. Whether it’s retrofitting existing systems or incorporating baffle walls into new construction projects, Protectolite’s expertise in FRP technology guarantees efficient and reliable wastewater treatment solutions.

When evaluating materials for baffle wall construction, it's clear why FRP (Fiber Reinforced Plastic) stands out as the superior choice:

Wood:

Traditionally used in baffle wall construction, wood exhibits several drawbacks compared to FRP. Wood is susceptible to decay, rot, and warping when exposed to moisture, compromising its structural integrity and longevity. Additionally, wood requires regular maintenance and may pose environmental concerns due to its sourcing.

Steel:

While steel offers strength and durability, it is prone to corrosion in wastewater treatment environments. Corrosion can weaken steel baffle walls over time, leading to structural failures and increased maintenance costs. Furthermore, steel's heavyweight nature necessitates significant labor and equipment for installation and maintenance.

FRP:

In contrast, FRP baffle walls combine the benefits of strength, durability, and corrosion resistance with lightweight properties. FRP's inherent resistance to corrosion ensures long-term performance in harsh wastewater treatment conditions. Moreover, FRP baffle walls require minimal maintenance, resulting in cost savings over their lifespan. Their lightweight nature simplifies installation, reducing labor and equipment expenses. Overall, FRP emerges as the superior choice for baffle wall applications, offering unmatched performance, longevity, and cost-effectiveness.