Our products have been chosen by a number of original equipment manufacturers across the country and abroad. We are chosen as a preferred composite parts supplier by a number of OEMs thanks to our proven track record of commitment to long-term vendor agreements.

When it comes to supplying composite parts to such strategic sectors as wastewater treatment, mass transit, electrical industry and military, it is often critical to have the entire process, from concept development to full production, handled by one single supplier. An approach like this ensures the consistency of the process, from the first steps of design, throughout the entire production cycle to the final product assembly.

That’s why Protectolite™ has expanded to become a one-stop shop for composite services to our customers. From concept development, design, prototyping, testing, tooling design & manufacturing to full production, Protectolite™ is your ultimate destination for all your composite needs.

With representatives throughout the USA and Canada, we are able to meet the demands of our customers no matter where they are located. With our well-planned logistics system and regularly replenished materials inventory, we can supply parts to the manufacturers with daily/year-round production across all of North America. We ship to a dozen plus OEM locations across the US and Canada every day, ensuring timely and safe delivery of our products with every shipment.

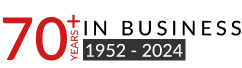

As a custom composite manufacturer, we understand the importance of each step in the manufacturing process. That is why our company boasts a full-service manufacturing facility with in-house engineering capabilities.

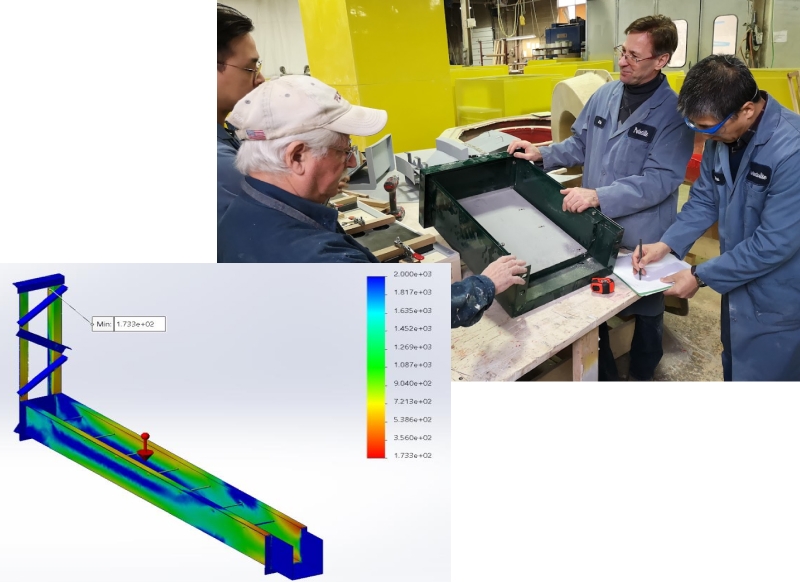

With CFD software, on-site R&D lab and Q&A facilities, we are able to design, modify and test any operational or design modifications before the product is sent to manufacturing.

We provide 3D models through SolidWorks, seismic loading and meteorological calculations as well as FEA analysis to ensure that each part is engineered, taking into account all possible seismic and meteorological conditions.

We offer the lowest water absorption (0.056%) fiber-reinforced plastics on the market in a submerged environment. Our products are compliant with AWWA F102 standards.

With 8 trained mechanical, fluid dynamics and chemical engineers on staff, we provide assurance to our clients that their project is in the hands of professionals.

We strive to achieve the most optimal product design that can withstand virtually any real-world physical effects without breaking or wearing out.